How Do Specific Metal Profiles Enhance Storm Resistance in Florida?

Why Storm Resistance Is the Ultimate Roofing Priority in Florida

If there’s one thing every Florida homeowner understands, it’s that nature doesn’t pull punches here. With hurricane season arriving like clockwork and storms intensifying year over year, choosing the right roofing material is no longer just about curb appeal — it’s about survival. This is where metal roofing profiles come into their own.

Not all metal roofs are created equal. In Florida, the specific profile of a metal roof — including its panel width, fastening system, seam design, and material thickness — directly influences how well it withstands hurricane-force winds, wind-driven rain, and flying debris.

And here’s the good news: the right profile can make your roof as formidable as the structure beneath it.

Understanding Metal Roofing Profiles: More Than Just a Look

What Is a Metal Roofing Profile?

A “profile” refers to the shape and engineering of the metal panels used on your roof. It defines how the panels interlock, where they’re fastened, and how they respond to wind, rain, and heat. In Florida, where wind uplift and water intrusion are constant threats, these elements matter more than ever.

The most common profiles in storm-resistant builds include:

- Standing seam panels

- Corrugated (exposed fastener) panels

- Snap-lock interlocking systems

- Metal shingles

Each has its advantages, but only a few are battle-tested for Florida’s Category 4–5 hurricanes.

Florida Building Codes Demand More Than the Minimum

UL, ASTM, and TAS Ratings — Decoding the Alphabet Soup

Florida’s building codes are among the most stringent in the U.S., especially in high-velocity hurricane zones (HVHZs) like Miami-Dade and coastal counties. That means metal roof profiles need certifications such as:

- UL 580 – Tests uplift resistance.

- ASTM E1592 – Measures structural performance under dynamic pressure.

- TAS 125 & UL 1897 – Examine wind uplift and pressure resistance.

Profiles like standing seam panels, with continuous vertical seams and hidden fasteners, often pass these tests with flying colors. Why? Their tight interlocking systems prevent wind from getting beneath panels — one of the top causes of roofing failures during storms.

Interlocking Panel Systems: Your First Line of Defense

Why Interlocking Panels Matter in Wind Uplift

In hurricane scenarios, wind doesn’t just push down — it pulls up. Known as wind uplift, this force can rip shingles or loosely fastened panels from a roof within minutes. Interlocking metal panels, especially those engineered with snap-lock or mechanically seamed systems, dramatically reduce this risk.

A well-installed interlocking system:

- Prevents panel shifting and lift

- Seals tightly against moisture intrusion

- Forms a near-monolithic surface from ridge to eave

According to Allstate Exteriors, metal roofing configured with interlocking systems can withstand winds up to 160 mph, easily meeting or exceeding hurricane standards.

The Standing Seam Advantage: Seamless Strength

What Makes Standing Seam Metal Roofing So Resilient?

If metal roofing had a VIP lounge, standing seam would be seated at the head of the table.

Standing seam systems feature raised vertical seams that interlock mechanically or with hidden fasteners. These systems run continuously from ridge to eave, minimizing horizontal breaks — which are notorious for allowing wind and water intrusion.

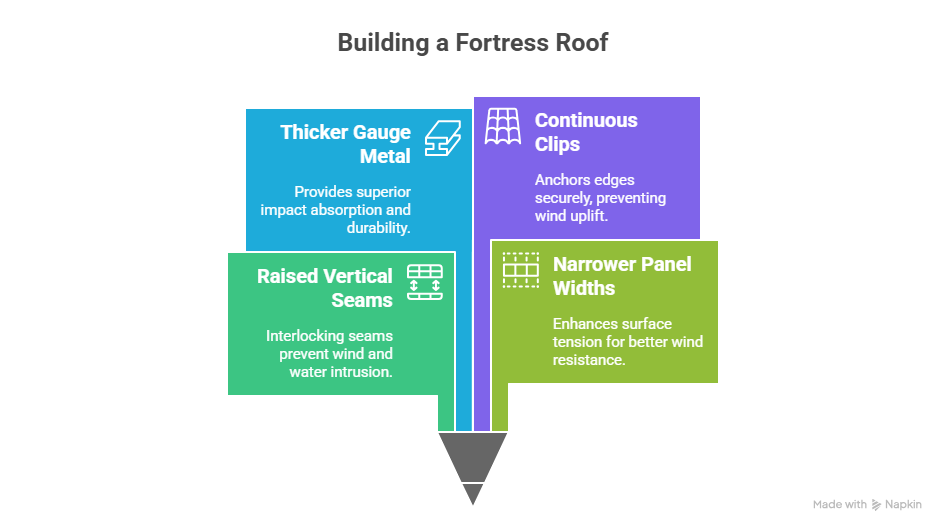

According to the McElroy Metal Blog, top-tier standing seam profiles:

- Use narrower panel widths for greater surface tension resistance

- Rely on thicker gauge metal for superior impact absorption

- Utilize continuous clips with tight corner spacing to anchor vulnerable edges

The result? A roof that not only looks sleek but holds firm against the wrath of a Category 5 hurricane.

Beyond Wind: Water, Salt, and Debris

Profiles Built to Block Water Intrusion

Wind may steal the headlines, but wind-driven rain is equally devastating. The wrong profile — especially those with exposed seams or fasteners — can become an open invitation for leaks.

Advanced metal profiles combat this with:

- Elevated seams that deflect rain like a shield

- Seamless installations that channel water away from fasteners

- Hidden clips and fastening systems to reduce penetrations

According to the experts at Roofing Nation, modern standing seam systems are tested to resist water intrusion even at 110 mph wind speeds — a benchmark only met by precision-engineered profiles.

Corrosion Resistance: Florida’s Salty Secret Enemy

Living near the ocean may sound idyllic, but for your roof? It’s a salt bath.

Salt-laden air accelerates corrosion, particularly in lower-grade metals. That’s why storm-resistant metal profiles in Florida often use galvalume, zinc-aluminum coated steel, or aluminum panels — all chosen for their superior corrosion resistance.

Coastal homeowners working with Top Hat Roofing can rest easy knowing that their metal roofs are designed specifically for Florida’s salt-heavy climate, using materials that withstand not only the storm but the slow, silent creep of corrosion.

Thicker Is Tougher: Why Gauge Matters

Understanding Metal Gauge

In roofing, gauge refers to the thickness of the metal. Counterintuitively, lower numbers mean thicker metal — for example, 24-gauge is thicker and stronger than 29-gauge.

Thicker metal is:

- More resistant to denting from hail and debris

- Less likely to warp or vibrate under high winds

- More structurally sound at longer spans

This matters when you’re facing storms with flying branches, hailstones, and intense pressure changes.

As noted in Metal Architecture, commercial-grade systems like those used at the Medalist Golf Club in Florida often opt for heavy-gauge metal and wide seam profiles, combining durability with aesthetics — and proving that storm-resistance can still look sharp.

Coming Up Next…

In Section 2, we’ll break down:

- The top three metal roofing profiles Florida contractors trust most

- How installation technique makes or breaks a roof’s storm performance

- Why profile choice can affect your insurance premiums and resale value

Stay tuned as we climb deeper into the science — and style — of stormproof roofing.

How Do Specific Metal Profiles Enhance Storm Resistance in Florida?

Florida’s Top Three Storm-Resistant Metal Roofing Profiles

Florida’s unique blend of coastal humidity, high winds, and intense storms has made metal roofing the preferred choice — but within that category, not all profiles perform equally. Contractors across the state consistently rely on a select few metal profiles that have proven themselves in real-world hurricane conditions. Here’s a closer look at the top three:

1. Standing Seam Panels: The Benchmark of Hurricane Performance

Among all profiles, standing seam is widely considered the most effective at withstanding Florida’s most aggressive weather systems.

Standing seam roofs feature continuous metal panels that run from ridge to eave, with seams elevated above the flat surface. These seams are either mechanically seamed or snap-locked, creating a tight barrier that resists wind uplift and water infiltration.

According to McElroy Metal, standing seam systems are often reinforced with:

- Thicker gauge metal (usually 24- or 26-gauge)

- Narrower panel widths for added rigidity

- Tight clip spacing at edges and corners

These features allow standing seam panels to withstand wind speeds exceeding 150 mph, meet rigorous ASTM E1592 and UL 580 certifications, and provide unmatched protection during Florida’s hurricane season.

2. Corrugated Metal Panels: Durable with Proper Fastening

While corrugated metal panels are often more affordable and easier to install, their storm performance depends heavily on installation technique.

Corrugated profiles are characterized by their exposed fasteners and wave-like shape, which can provide excellent structural strength when installed with proper spacing and fastener alignment. However, these systems are more vulnerable to wind-driven rain and uplift if fasteners are overtightened, under-tightened, or misaligned.

That said, when installed using Florida-approved techniques and high-quality sealant washers, corrugated metal roofs can resist winds up to 140 mph and provide solid impact resistance. They’re a common choice in non-coastal areas or on agricultural and utility structures, where budget may be a factor.

Per Roofing Nation, these profiles have improved significantly in recent years thanks to updated codes and better manufacturing tolerances, though they still trail standing seam in overall storm resilience.

3. Metal Shingles: A Stylish, Resilient Option

Metal shingles might not look like a typical hurricane shield, but don’t let the aesthetics fool you. These interlocking systems combine the visual appeal of asphalt or slate with the durability of metal — and they pack a serious punch in storm resistance.

Metal shingles are engineered to lock tightly on all four sides, providing:

- A continuous barrier against wind uplift

- Resistance to water penetration at overlaps

- Class 4 impact ratings for hail and flying debris

They’re often coated with corrosion-resistant finishes and installed using hidden fasteners, helping them meet or exceed Miami-Dade’s strict building codes. Metal shingle systems also carry certifications like UL 1897 and TAS 125, which specifically test for wind-driven rain and edge uplift resistance.

According to Allstate Exteriors, metal shingles can handle wind speeds up to 160 mph, making them a top-tier option for homeowners who want both function and flair.

Installation Is Everything: Why Even the Best Profile Can Fail

Even the most engineered metal roofing profile can become a liability if improperly installed. In storm-prone states like Florida, installation technique is just as critical as material selection.

Factors That Influence Performance:

- Fastener placement and tightness: A loose or misaligned fastener can become a point of failure during high winds.

- Clip spacing: Particularly at roof corners and edges, spacing must comply with Florida HVHZ requirements.

- Underlayment type: Synthetic underlayment, peel-and-stick barriers, and water shields are essential in managing secondary moisture intrusion.

- Ridge and eave detailing: Water entry often occurs at these vulnerable transitions, making flashing and trim critical for storm resilience.

Working with certified professionals, like those at Top Hat Roofing, ensures the chosen profile performs to its full potential. Their trained crews understand Florida’s building code requirements and tailor installations to maximize wind and water resistance.

Don’t Forget the Fasteners: Hidden vs. Exposed Systems

One of the most overlooked contributors to storm resistance is fastener visibility and protection.

- Exposed fastener systems, like traditional corrugated panels, are easier to install but more vulnerable to leaks and corrosion over time, especially if the washers degrade or fasteners loosen during thermal expansion.

- Hidden fastener systems, used in standing seam and metal shingle applications, not only enhance aesthetics but protect the anchoring points from wind, moisture, and UV exposure.

Many Florida contractors now exclusively use hidden fastener profiles for coastal homes due to the reduced risk of water intrusion and uplift failure during major storms.

What’s Beneath the Panels: The Importance of Roof Decking

No matter how tough your metal profile is, it needs a strong foundation.

Most modern storm-resistant roofing systems in Florida are installed over:

- 5/8” plywood or OSB decking

- Peel-and-stick underlayment membranes

- Ventilated attic spaces to reduce pressure buildup

The right decking system anchors the metal panels and fasteners, distributes wind loads, and supports the entire roof structure during extreme weather. Top Hat Roofing includes decking assessments in every new metal roof project, ensuring that storm resilience starts from the bottom up.

Coming Up in Section 3…

In the final section, we’ll explore:

- The long-term value of choosing the right metal profile

- How insurance companies view different profiles

- Real-life examples of performance during hurricanes

- Smart homeowner tips for roof inspection and maintenance

How Do Specific Metal Profiles Enhance Storm Resistance in Florida?

Metal Roof Profiles and Long-Term Value in Hurricane Country

Choosing a storm-rated metal roofing profile isn’t just about riding out the next hurricane. It’s a decision that brings tangible long-term benefits — financial, structural, and environmental. While the upfront investment may be higher than traditional materials, the durability and low maintenance of high-performance metal profiles create serious value over time.

According to Kelly Roofing, the right metal roof can last 40–70 years with proper installation and maintenance — nearly three times longer than asphalt shingles. This makes it one of the most cost-effective long-term upgrades for Florida homes.

Insurance Impacts: Why the Right Profile Can Lower Premiums

Insurance companies in Florida are increasingly offering premium discounts to homeowners with roofing systems that meet or exceed hurricane codes. Metal roofing profiles that carry certifications such as:

- UL 580 for uplift resistance

- ASTM E1592 for wind pressure

- TAS 125 for severe wind-driven rain

are viewed favorably by insurers because they’re statistically less likely to fail during a storm.

Some insurers even require engineering documentation or a Florida Product Approval Number to qualify for policy discounts, which many modern metal profiles — particularly standing seam and interlocking shingle systems — already include.

Contractors like Top Hat Roofing are familiar with these code requirements and can install metal roofing systems that not only protect your home but reduce long-term insurance costs.

Real Storm, Real Proof: How Profiles Perform in the Field

Florida doesn’t lack case studies — every hurricane season brings with it a litmus test for construction quality. Metal roofs with high-performance profiles have consistently shown exceptional resilience during major events:

Hurricane Ian (2022):

In counties like Lee and Charlotte, homes with standing seam metal roofs remained intact even after winds exceeding 150 mph, while many shingle roofs were completely stripped. Post-storm aerial surveys confirmed that metal roofing with interlocking systems had the lowest failure rate in affected areas.

Hobe Sound, Florida – Medalist Golf Club:

As highlighted in Metal Architecture, the Medalist Golf Club features a custom panelized metal roofing system with a broad-width seam and floating clip design. After repeated tropical systems and seasonal storms, the structure remains undamaged — a real-world example of how the right profile and precision installation pay off.

Maintenance Tips: Protecting Your Investment After the Storm

Storm resistance isn’t just about the roof you install — it’s also about how you maintain it. The good news? Metal roofing requires far less maintenance than other materials. But post-hurricane season, it’s smart to do a few key things:

1. Inspect Panel Seams and Fasteners

Look for any shifting, loosened clips, or panel separation. Even the most durable system can suffer if flashing or fasteners have been compromised.

2. Clear Debris

Branches and flying objects can dent panels or damage paint coatings. Regular cleaning prevents corrosion and ensures full drainage from valleys and gutters.

3. Schedule a Professional Inspection

Florida contractors like Top Hat Roofing offer post-storm inspections to evaluate structural integrity, identify hidden damage, and make minor repairs that preserve the roof’s warranty.

Beyond Hurricanes: Year-Round Florida Benefits

Storm resistance may be the headline feature of metal roof profiles, but the perks continue throughout the year:

- UV Reflectivity: Many metal roofs reflect solar radiation, reducing attic temperatures and lowering HVAC costs.

- Fire Resistance: Non-combustible materials like steel and aluminum reduce the risk of fire damage.

- Pest Resistance: Unlike shingles or tiles, metal panels are far less hospitable to nesting insects and rodents.

- Sustainability: Metal roofs are often made from recycled materials and are 100% recyclable at the end of their lifespan.

Combined with their energy efficiency and aesthetic versatility, metal profiles are one of the smartest long-term roofing choices for Florida homeowners — not just during hurricane season, but every day of the year.

Conclusion: The Right Profile Is Your Roof’s Superpower

In Florida’s storm-prone climate, choosing a specific metal roofing profile isn’t just a construction decision — it’s a strategic investment in resilience. From standing seam systems with their elevated wind resistance, to interlocking metal shingles that offer both style and substance, the right metal profile fortifies your home against the elements while offering peace of mind.When installed by a trusted expert like Top Hat Roofing, your roof becomes more than just a barrier — it becomes a battle-tested shield, built to endure not just one storm, but decades of Florida weather.